Complete wood pellet production line has kinds of machines, which are essential or support equipment for biomass or wood pellet production. Complete wood pellet line is also called biomass pellet production line, wood pellet production line, wood pelletizing line, complete wood pellet plant, and etc.

According to the types of machines, we divide wood pellet production line into 5 systems, including hammer mill system, dryer system, pellet mill system, cooler system and packer system. The raw materials of wood pellet production line are wood, straw, rice husk, pine and other biomass raw materials.

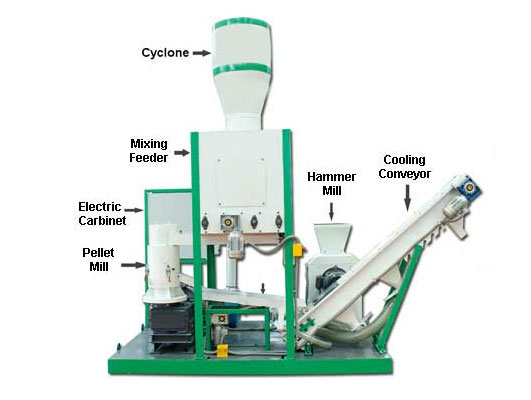

The process of making wood pellets includes chipping, crushing, drying, pelletizing, cooling screening, packing. The pellet production machines have wood chipper, hammer mill, mixer, dryer, conveyor, pellet mill (small pellet mill or ring die pellet mill), cooler, packer and etc. Of course, the specific needs of each user are different, customers can choose the most suitable production process according to their own raw materials and needs.

Hammer mill is very important in the production line of wood pellet, it can process raw materials such as straw, husk, wood chips, branches, forest waste into powder materials, so that their size can be suitable for pelletizing of pellet machine. Hammer mill is an ideal machine of crushing biomass raw materials, we can provide one type of hammer mill according to your needs.

GEMCO has biomass drum dryer and air flow dryer. Drum dryer is pided into single cylinder drum dryer and three cylinder drum dryer.

Wood pellet mill is usually small pellet mill, which has multiple models. You can choose the most suitable one according to your own raw materials, the output, motor and other parameters.

GEMCO cooler is the special equipment that can be used in cooling and screening of wood pellets. The cooler possesses the characteristics of high screening efficiency, low noise, small dust, long service life, simple maintenance and operation, etc.

More support machines or other types of machines, please contact us.

We all know that pellet mill is an essential machine for making wood or biomass pellets, but our raw materials always are not always suitable for pellet mill, such as wood and other large size biomass raw materials. These raw materials should be crushed before pelletizing. Besides, the raw materials for pelletizing need to have appropriate water content. And the made pellets should be cooled for packing. The package helps to better store and transport.

GEMCO is a high-tech enterprise specializing in the production of biomass molding machinery (biomass pellet machine and wood pellet production line) and renewable energy equipment.

Complete wood pellet production line is suitable for large factory or users. If you want to build your own wood pellet production line, we can design the most suitable processing plan and the production line according to your raw materials and needs.

This is the simplest combination. If you want to make wood pellets at home, this is a good choice.

It's more automatic. The conveyor saves the trouble of artificial feeding and improves the efficiency of the work.

Wood pellet production line can be consisted of one or multiple machines according to the needs of customers. It is flexible and configured according to different users. Contact us soon for building your own wood pellet production line.

Diesel pellet machine and screw conveyor are specially designed for our customer. The trial run is successful. Welcome to consult and order....

Diesel pellet machine and screw conveyor are specially designed for our customer. The trial run is successful. Welcome to consult and order....